0295

- Industry Power

- Problem Corrosion / Erosion

- Country United States

-

Project Goal

To protect from further erosion and corrosion

- Products Used CeramAlloy CP+AC

- Status Completed

CeramAlloy Saves Down-Time & Aggravation for Power Plant Engineers

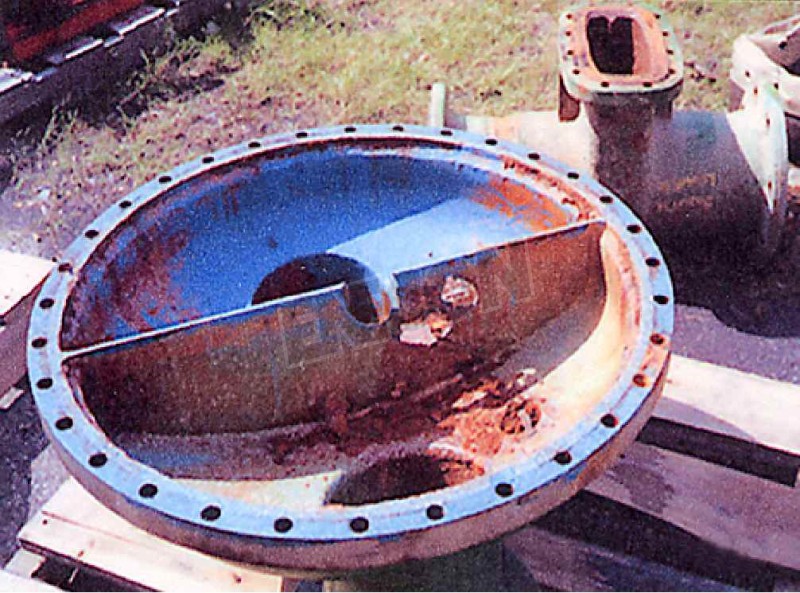

During the first weekend of a scheduled outage, this coal fired power plant in the southeastern United States discovered some extensive but unexpected damage to a number of heat exchanger components.

Their initial solution to the problem- the purchase of replacement units – proved ineffective when, on Monday morning, the plant learned that the delivery time would mean extending the shutdown beyond the allotted time for the outage.

The plant then immediately contacted the local ENECON Sales Director, Bob Hedreen, and explained the situation. Bob was onsite that afternoon and, after contacting a local contractor experienced in working with ENECON systems, submitted a proposal that evening for the work that would be necessary.

After receiving the go ahead for the project, the components were picked up on Tuesday and the repair activities were underway that same afternoon.

The rebuilding of the holed areas involved the use of metal screening and CeramAlloy CP+[AC] to bridge the gaps and build up the required thickness. After grinding the CP+[AC] to complete the system and protect the equipment from further erosion and corrosion.

The repaired components were returned to the plant on Friday and installed over the weekend – enabling the plant to be back in operation on Monday morning as originally planned.