RESURFACING, COATING AND PROTECTING.

SUPERIOR STRENGTH, DURABILITY AND ADHESION WITH FLEXIBILITY, ABRASION RESISTANCE, AND ELONGATION.

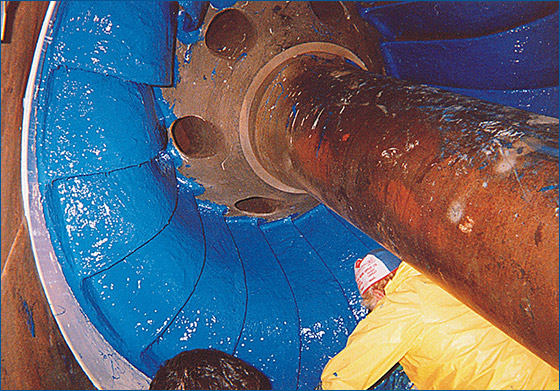

FLEXICLAD DuraTough DL is a two component, 100% solids, fluid consistency elasto-ceramic polymer composite specifically formulated to surface and protect equipment subject to cavitation accelerated erosion/corrosion.

DuraTough combines the superior strength, durability and adhesion of an epoxy with the exceptional flexibility, abrasion resistance and shock absorbency of an elastomeric urethane.

Flexiclad DuraTough DL is ideal for coating, resurfacing & protecting equipment prone to cavitation attack as well as creating and repairing flexible seals, gaskets, seats, etc., on machinery and equipment such as heat exchangers, pumps, valves & piping systems.

- Cavitation Resistant

- Requires No Heat

- Excellent Adhesion

- 100% Solids

- Exceptional Flexibility

- Coating

- Resurfacing

- Protecting

- Creating and Repairing Flexible Seals

- Gaskets & Seats

| Mixing ratio | Base | Activator |

|---|---|---|

| By Volume | 5.7 | 1 |

| By Weight | 6.5 | 1 |

Related Images

DuraTough DL

Physical Properties

| Typical Values | Test Method | ||

|---|---|---|---|

| Hardness - Shore D | 55 | ASTM D-2240 | |

| Tensile Shear Adhesion | |||

| Steel | 1200 psi | 84 kg/cm2 | ASTM D-1002 |

| Aluminum | 1050 psi | 74 kg/cm2 | ASTM D-1002 |

| Copper | 1200 psi | 84 kg/cm2 | ASTM D-1002 |

| Stainless Steel | 1100 psi | 77 kg/cm2 | ASTM D-1002 |

| Peel Adhesion | greater than 30 pli | ASTM D-1876 | |

|

Comparative Cavitation Resistance -Frequently: 20 KHZ; amplitude: 0.001 inches |

ASTM G-32 | ||

| 316 Stainless steel | 60 microns | CMDL* | |

| DuraTough™ DP | 50 microns | CMDL* | |

| Carbon Steel | 240 microns | CMDL* | |

| *Cumulative Mean Depth of Loss | |||

Working Life and Cure Times

| Ambient Temperature | Working Life | Initial Set | Maximum Overcoating | Full Cure | |

|---|---|---|---|---|---|

| 41°F | 5°C | 50 min. | 4 hrs. | 12 hrs. | 5 days |

| 59°F | 15°C | 45 min. | 2 hrs. | 8 hrs. | 4 days |

| 77°F | 25°C | 30 min. | 1 hrs. | 6 hrs. | 3 days |

| 86°F | 30°C | 15 min. | 45 min. | 4 hrs. | 36 hrs. |

Colors

Green

Haze Gray

Note: Other colors are available on a “special order” basis. However, there are minimum / multiple quantity requirements for such orders and there may be an increase in cost. Additionally, due to formulation restrictions, not all colors are possible for all materials. Speak to your local ENECON Sales Representative for more information.

Due to monitor / printer differences, actual colors may vary slightly from the representations appearing in this chart.

Chemical Resistance

| Acetic acid (10%) | NR | Methanol | NR |

| Ammonium hydroxide (10%) | G | Mineral Oil | G |

| Ammonium hydroxide (30%) | NR | Oxalic acid | G |

| Butyl cellosolve | NR | Phosphoric acid (10%) | G |

| Ethanol | NR | Phosphoric acid (50%) | NR |

| Ethanol glycol | G | Sodium hydroxide (10%) | EX |

| Hexane | G | Sodium hydroxide (50%) | EX |

| Hydrochloric acid (10%) | G | Sulfuric acid (10%) | G |

| Isoprophyl alcohol | G | Toluene | NR |

| MEK | NR | Trichloroethylene | NR |

EX - Suitable for most applications including immersion

G - Suitable for intermittent contact, splashes, etc.

NR - Not Recommended