THE LEAK STOPPER – AND MORE!

The First Choice for Fast, Reliable Mechanical Repairs.

Available in unique, convenient ENECON® ‘A – Packs.’

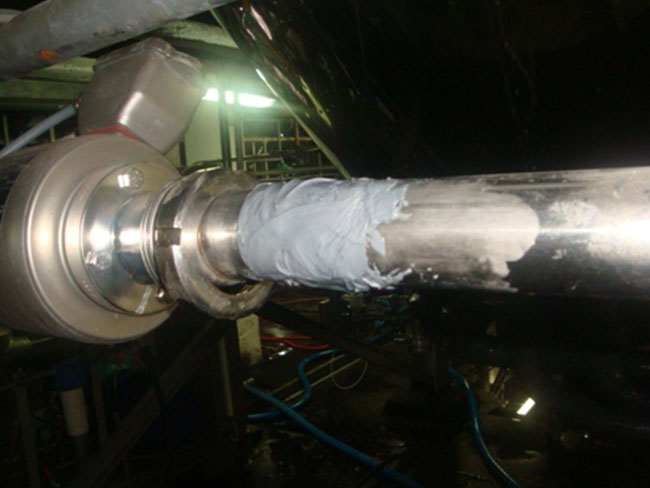

METALCLAD SpeedAlloy is a quick curing, 100% solids, polymeric ‘leak stopper’ used for making fast, effective repairs to equipment which must be returned to service almost immediately.

METALCLAD SpeedAlloy has a paste consistency when first mixed then transforms into a metal-hard composite in just minutes.

- Quick Curing

- Trowelable

- Requires No Heat

- Unlimited Shelf Life

- 100% Solids

- Safe & Simple To Use

- Pipes & Tanks

- Sumps

- Radiators & Fuel tanks

- Cracked & holed casings

- Damaged keyways

- Stripped threads

- Scored shafts & Hydraulic Rams

Related Images

SpeedAlloy

Physical Properties

| Typical Values | Test Method | ||

|---|---|---|---|

| Compressive strength | 22,500 psi | 1575 kg/cm2 | ASTM D-695 |

| Flexural strength | 8,500 psi | 595 kg/cm2 | ASTM D-790 |

| Izod impact strength | 1.3 ft lbs/in | 0.69 j/cm | ASTM D-256 |

| Hardness - Rockwell | R-90 | ASTM D-785 | |

| Hardness - Shore D | 84 | ASTM D-2240 | |

| Tensile Shear Adhesion | |||

| Steel | 2300 psi | 161 kg/cm2 | ASTM D-1002 |

| Aluminum | 2100 psi | 147 kg/cm2 | ASTM D-1002 |

| Copper | 2250 psi | 158 kg/cm2 | ASTM D-1002 |

| Stainless Steel | 1800 psi | 126 kg/cm2 | ASTM D-1002 |

| Surface resistivity | 1 x 1015 ohms | ASTM D-257 | |

| Volume resistivity | 1 x 1015 ohm/cm | ASTM D-257 | |

| Dielectric constant | 7.5 | ASTM D-150 | |

Working Life and Cure Times

| Ambient Temperature | Working Life | Machining Light Load | Full Mechanical | Chemical Immersion | |

|---|---|---|---|---|---|

| 41°F | 5°C | 10 min. | 60 min. | 2 hrs. | 72 hrs. |

| 59°F | 15°C | 7 min. | 45 min. | 1 hrs. | 48 hrs. |

| 77°F | 25°C | 5 min. | 30 min. | 40 min. | 36 hrs. |

| 86°F | 30°C | 3 min. | 20 min. | 30 min. | 24 hrs. |

| Mixing ratio | Base | Activator |

|---|---|---|

| By Volume | 1 | 1 |

| By Weight | 2 | 1 |

Chemical Resistance

| Acetic acid (0-10%) | EX | Methyl alcohol | G |

| Acetic acid (10-20%) | G | Methyl ethyl ketone | G |

| Acetone | G | Nitric acid (0-10%) | EX |

| Aviation fuel | EX | Nitric acid (10-20%) | G |

| Butyl alcohol | EX | Phosphoric acid (0-5%) | EX |

| Calcium chloride | EX | Phosphoric acid (5-10%) | G |

| Crude oil | EX | Potassium chloride | EX |

| Diesel fuel | EX | Propyl alcohol | EX |

| Ethyl alcohol | G | Sodium chloride | EX |

| Gasoline | EX | Sodium hydroxide | EX |

| Heptane | EX | Sulfuric acid (0-10%) | EX |

| Hydrochloric acid (0-10%) | EX | Sulfuric acid (10-20%) | G |

| Hydrochloric acid (10-20%) | G | Toluene | G |

| Kerosene | EX | Xylene | EX |

EX - Suitable for most applications including immersion

G - Suitable for intermittent contact, splashes, etc.