OUTSTANDING EROSION/CORROSION RESISTANCE – EVEN AT ELEVATED TEMPERATURES!

METALCLAD® CeramAlloy® HTL is a two component, 100% solids, liquid polymer composite used for repairing, resurfacing and coating both damaged and new components to provide outstanding erosion and corrosion resistance at elevated temperatures.

When mixed, CeramAlloy® HTL is a viscous liquid. CeramAlloy® HTL cures to a hard, ceramic-like material with an extremely smooth surface finish. It has been specifically developed for elevated temperature applications.

METALCLAD® CeramAlloy® HTL is a High Performance Polymer Composite for resurfacing and protecting all types of fluid flow equipment from aggressive erosion and corrosion damage especially at elevated temperatures.

Colors

Dark Brown

Light Brown

Note: Other colors are available on a “special order” basis. However, there are minimum / multiple quantity requirements for such orders and there maybe an increase in cost. Additionally, due to formulation restrictions, not all colors are possible for all materials. Speak to your local ENECON Sales Representative for more information.

Due to monitor / printer differences, actual colors may vary slightly from the representations appearing in this chart.

- Apply by Brush, Roller or Flexible Applicator

- Requires No Heat

- Unlimited Shelf Life

- 100% Solids

- Safe & Simple To Use

- Heat Exchanger & Scrubbers

- Pumps & Stacks

- Valves & Pipework

- Housings & Tanks

- Drum Dryers

- Tube Sheets & Water Boxes

- Distillation Units

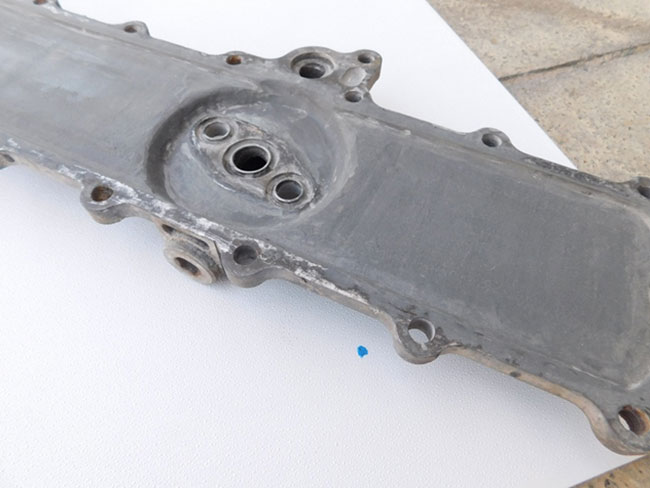

Related Images

ceramalloy-htl

| Mixing ratio | Base | Activator |

|---|---|---|

| By Volume | 3 | 1 |

| By Weight | 4.6 | 1 |

Temperature Guidelines

Up to:

Dry - 500°F / 260°C

Wet - 320°F / 160°C

We would always recommend that elevated temperature applications be discussed with your local ENECON Fluid Flow Systems Specialist.

Working Life and Cure Times

| Ambient Temperature | Working Life | Machining Light Load | Full Mechanical | Chemical Immersion | |

|---|---|---|---|---|---|

| 59°F | 15°C | 1.5 hrs | 20 hrs. | 48 hrs. | 5 days |

| 77°F | 25°C | 40 min. | 10 hrs. | 18 hrs. | 3 days |

| 86°F | 30°C | 25 min. | 7 hrs. | 15 hrs. | 2 days |

Physical Properties

| Typical Values | Test Method | ||

|---|---|---|---|

| Compressive strength | 12,000 psi | 840 kg/cm2 | ASTM D-695 |

| Flexural strength | 8,500 psi | 595 kg/cm2 | ASTM D-790 |

| Hardness - Shore D | 87 | ||

| Tensile Shear Adhesion | |||

| Steel | 4000 psi | 280 kg/cm2 | ASTM D-1002 |

| Aluminum | 2500 psi | 175 kg/cm2 | ASTM D-1002 |

| Copper | 3000 psi | 210 kg/cm2 | ASTM D-1002 |

| Stainless Steel | 4100 psi | 287 kg/cm2 | ASTM D-1002 |

Chemical Resistance

| Ammonia (5%) | EX | NaCl (5%) | EX |

| HCL (20%) | G | Sulfuric acid (98%) | G |

| Motor oil | EX | Sulfuric acid (50%) | EX |

EX - Suitable for most applications including immersion

G - Suitable for intermittent contact, splashes, etc.