REBUILDS EQUIPMENT DAMAGED BY CAVITATION.

SUPERIOR STRENGTH, DURABILITY AND ADHESION WITH FLEXIBILITY, ABRASION RESISTANCE AND ELONGATION.

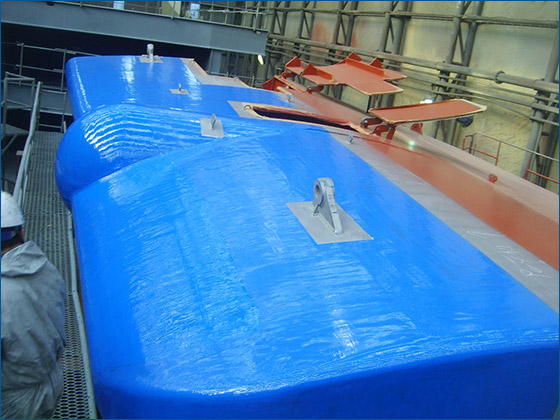

FLEXICLAD DuraTough DP is a two component, 100% solids elasto-ceramic polymer composite specifically formulated to rebuild equipment prone to cavitation attack and subsequent damage.

DuraTough combines the superior strength, durability and adhesion of an epoxy with the exceptional flexibility, abrasion resistance and shock-absorbency of an elastomeric urethane.

FLEXICLAD DuraTough DP is ideal for rebuilding cavitated areas as well as creating or rebuilding flexible seals, gaskets, seats, etc, on machinery and equipment such as heat exchangers, pumps, valves and piping systems.

- Cavitation Resistant

- Requires No Heat

- Excellent Adhesion

- 100% Solids

- Exceptional Flexibility

- Conveyor Belts

- Hoses

- Damaged Sidewalls on Off Road Tires

- Resilient Bonding of Metals, Woods, etc.

Creating / Repairing Flexible Seals - Expansion Bellows

- Gaskets & Seats

| Mixing ratio | Base | Activator |

|---|---|---|

| By Volume | 4 | 1 |

| By Weight | 4 | 1 |

Physical Properties

| Typical Values | Test Method | ||

|---|---|---|---|

| Hardness - Shore D | 50 | ASTM D-2240 | |

| Tensile Shear Adhesion | |||

| Steel | 1000 psi | 70 kg/cm2 | ASTM D-1002 |

| Aluminum | 950 psi | 67 kg/cm2 | ASTM D-1002 |

| Copper | 900 psi | 63 kg/cm2 | ASTM D-1002 |

| Stainless Steel | 850 psi | 60 kg/cm2 | ASTM D-1002 |

| Peel Adhesion | -greater than 40 pli | ASTM D-1876 | |

|

Comparative Cavitation Resistance -Frequently: 20 KHZ; amplitude: 0.001 inches |

ASTM G-32 | ||

| 316 Stainless steel | 60 microns | CMDE* | |

| DuraTough™ DP | 100 microns | CMDE* | |

| Carbon Steel | 240 microns | CMDE* | |

| *Cumulative Mean Depth of Erosion | |||

Working Life and Cure Times

| Ambient Temperature | Working Life | Initial Set | Maximum Overcoating | Full Cure | |

|---|---|---|---|---|---|

| 41°F | 5°C | 150 min. | 6 hrs. | 12 hrs. | 5 days |

| 59°F | 15°C | 120 min. | 3 hrs. | 8 hrs. | 4 days |

| 77°F | 25°C | 60 min. | 2 hrs. | 6 hrs. | 3 days |

| 86°F | 30°C | 45 min. | 90 min. | 4 hrs. | 36 hrs. |

Chemical Resistance

| Acetic acid (10%) | NR | Methanol | NR |

| Ammonium hydroxide (10%) | G | Mineral Oil | G |

| Ammonium hydroxide (30%) | NR | Oxalic acid | G |

| Butyl cellosolve | NR | Phosphoric acid (10%) | G |

| Ethanol | NR | Phosphoric acid (50%) | NR |

| Ethanol glycol | G | Sodium hydroxide (10%) | EX |

| Hexane | G | Sodium hydroxide (50%) | EX |

| Hydrochloric acid (10%) | G | Sulfuric acid (10%) | G |

| Isoprophyl alcohol | G | Toluene | NR |

| MEK | NR | Trichloroethylene | NR |

EX - Suitable for most applications including immersion

G - Suitable for intermittent contact, splashes, etc.

NR - Not Recommended