0207

- Industry Facilities Maintenance

- Problem Corrosion / Erosion

- Country United States

-

Project Goal

Repair & Protect

- Products Used CeramAlloy CL+AC and CeramAlloy CP+AC

- Status Completed

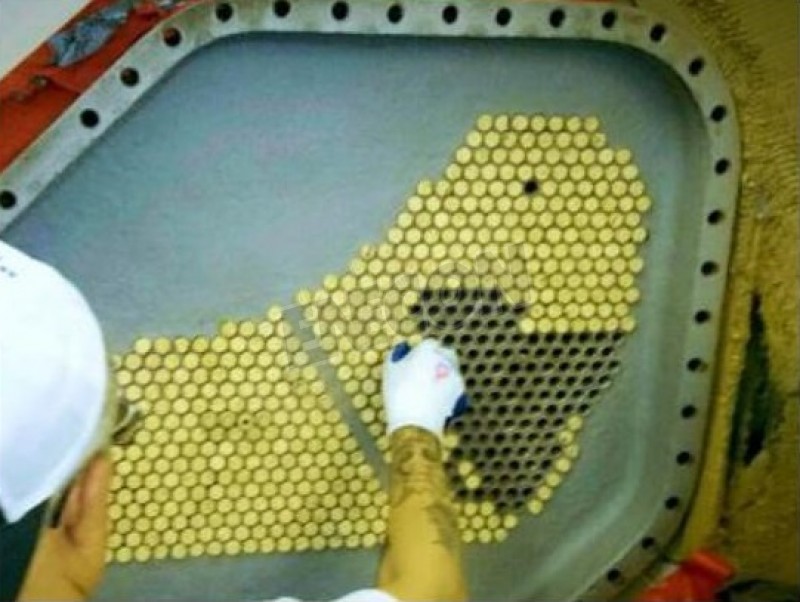

A Denver office building was dealing with a large, 35 year old chiller that had begun to leak around the gasket. Upon inspection it was discovered that there were several causes of the leak. Years of use of a daisy style gasket had exposed sections of the flange face to erosion and corrosion. The inside face of the box near the flange was eroded as well as a groove worn into the end cap.

The building’s maintenance manager was about to attempt the repair with three different companies welding, grinding and coating the unit. The ENECON single source solution made much more sense to the maintenance manager.

After grit blasting, METALCLAD CeramAlloy CP+AC was used for rebuild. Two coats of CeramAlloy CL+AC were then applied to protect these components from future erosion / corrosion damage. ENECON was able to bring this huge 18 foot long, 35 year old unit back into service and deliver a solution designed to give them many years of additional service.