0165

- Industry Food and Beverage

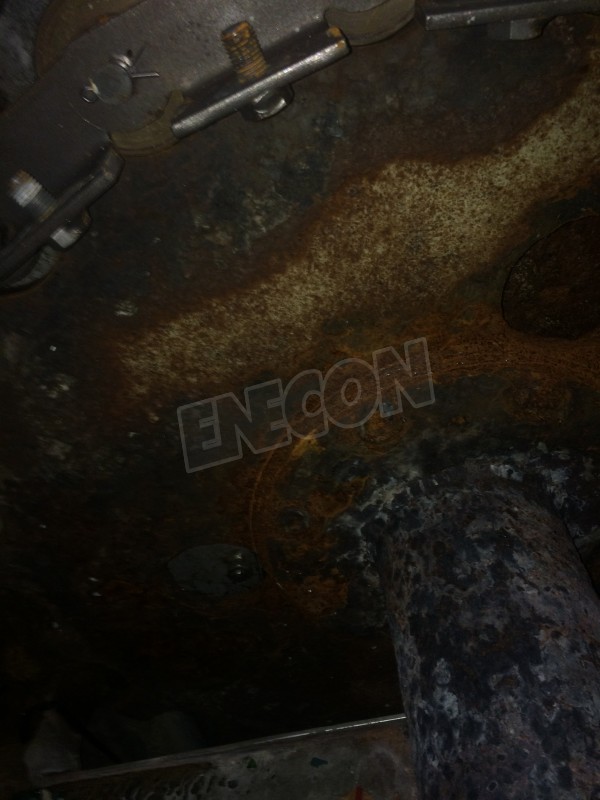

- Problem Chemical Attack and Corrosion / Erosion

- Country Cyprus

-

Project Goal

To rebuild and protect shaft

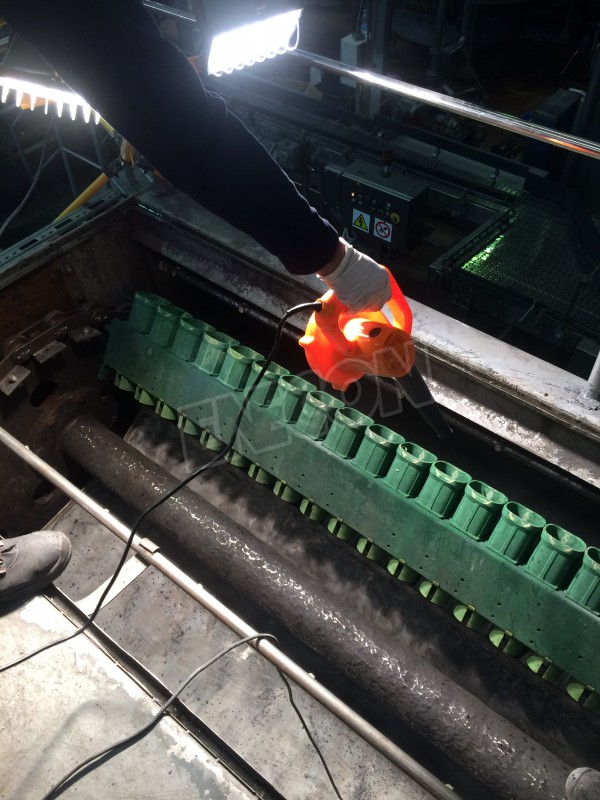

- Products Used CHEMCLAD XC and DurAlloy

- Status Completed

Client was experiencing problems in a critical section of the cycle of bottling beers. The shaft that its work was to operate the bottle washer was facing severe deterioration and it was literary falling apart with metal parts coming out with bare hands.

This operation was continuous and downtime was not a choice.

We were called in and in 2 days we managed to provide back the shaft fully in operational mode.

Our works included grinding and manually sanding in order to remove all loose metal parts and corrosion. We washed all areas (shaft and side walls) with plenty of water and prior to commencing application of our polymers we cleaned off with acetone.

All areas needed build up were captured using DurAlloy, our fast setting 2 component paste high performance polymer paste. Then we applied by brush and rollers two coats of CHEMCLAD XC in order for the components to remain unharmed from the various chemicals used during washing process.

Client was very satisfied as we not only managed to save them thousands of Euros in replacement costs but we also managed to do so in just a few days.