0213

- Industry Food and Beverage

- Problem Corrosion / Erosion

- Country United States

-

Project Goal

Repair & Protect

- Products Used CeramAlloy CL+AC and CeramAlloy CP+AC

- Status Completed

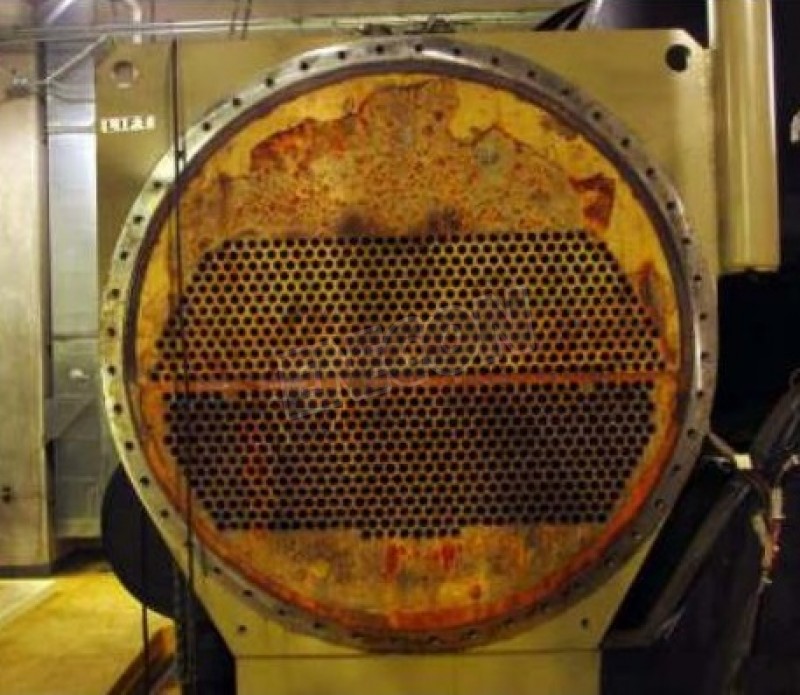

At the corporate headquarters of a major food manufacturer in Minnesota, three chillers had serious erosion and corrosion problems on the tube sheets and heads. Containment of the dust created from grit blasting was a major concern at this facility.

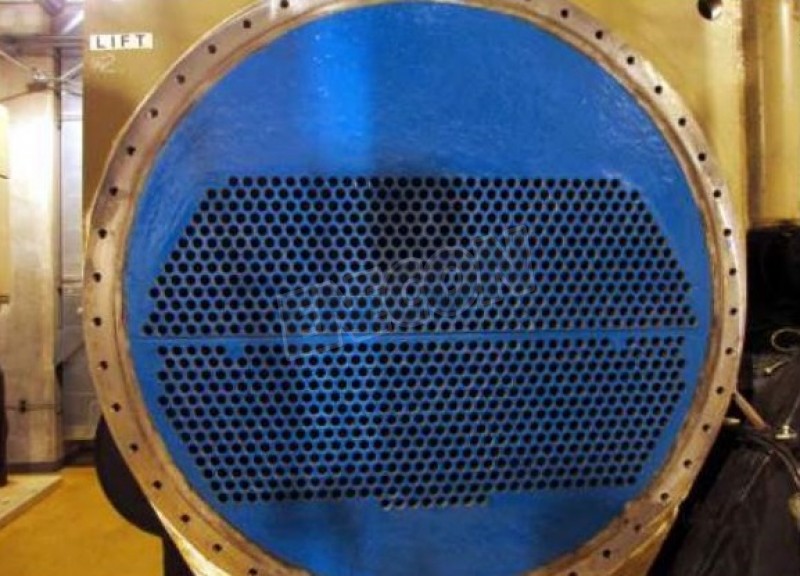

The decision was made to utilize Sponge Jet technology resulting in a reduction of 98% of the dust created by standard grit blasting. This would allow multiple crews to work concurrently on all three chillers. Each day one complete chiller (two tube sheets / two heads) was blasted allowing the field application crew of ENECON Minnesota to begin the application process consisting of METALCLAD CeramAlloy CP+AC to rebuild the deteriorated areas and METALCLAD CeramAlloy CL+AC to protect the chiller’s components from future deterioration. The three chillers were completed in six days.

The result was a cost savings to the customer while minimizing the time it took to complete the project.