0149

- Industry Facilities Maintenance

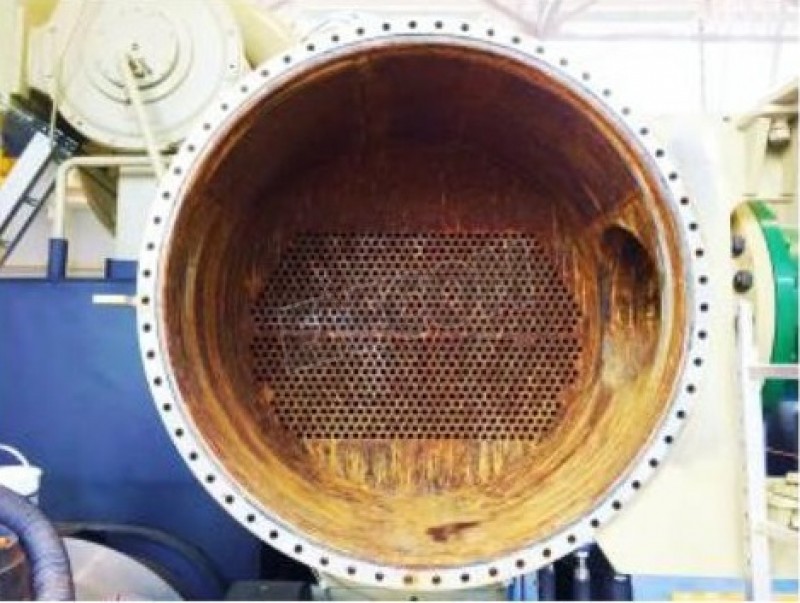

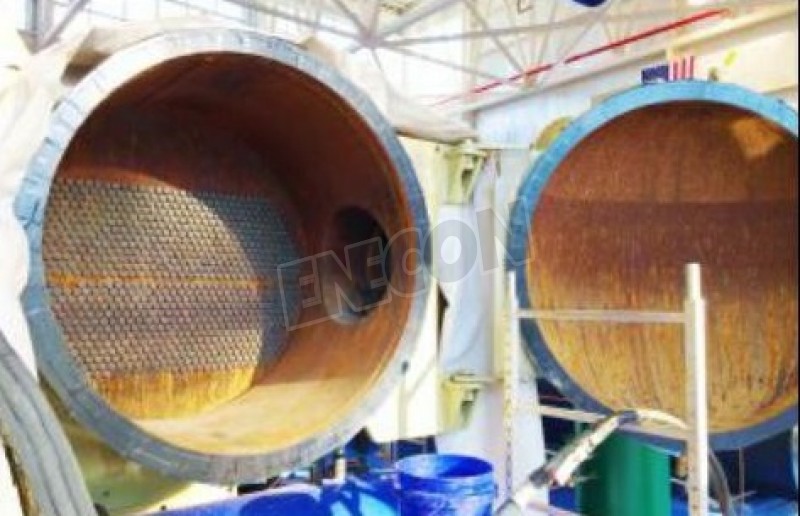

- Problem Corrosion / Erosion

- Country United States

-

Project Goal

Protection

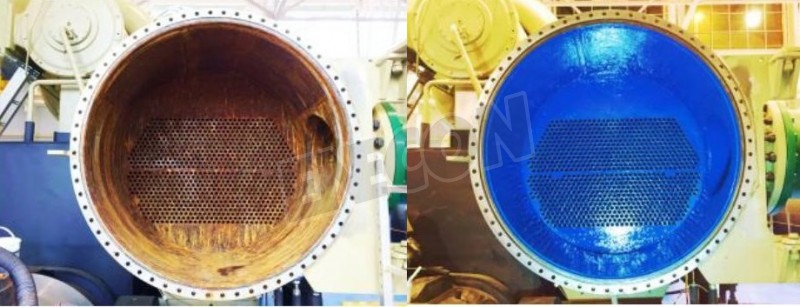

- Products Used CeramAlloy CL+AC

- Status Completed

This prestigious university owns one of the largest air conditioning plants in North Carolina, currently consisting of eleven 3,700 ton chillers. The maintenance engineers had difficulty finding a company that was capable of protecting these chillers using an acceptable repair procedure with the strong attention to detail demanded by the university. The local ENECON distributor was contacted and was asked to coat an existing chiller so the application process could be observed.

The chillers were dried out when the ENECON team arrived. After grit blasting the surface, a two coat CeramAlloy CL+AC system was applied under the watchful eyes of the maintenance engineers. After completing the chiller to the satisfaction of the university’s maintenance team, the local ENECON distributor was subsequently asked to coat two more chillers. Based on these outstanding results, the university has committed to coating the remaining chillers as temperature and budgets allow.

METALCLAD CeramAlloy CL+AC is a 100% solids, two component, liquid polymer composite used for repairing, resurfacing and coating components to provide outstanding fluid flow erosion and corrosion resistance. For more information about METALCLAD CeramAlloy CL+AC please visit: METALCLAD CeramAlloy CL+AC