0112

- Industry Marine

- Problem Corrosion / Erosion

- Country Greece

-

Project Goal

Repair worn shafts for yacht

- Products Used CeramAlloy CL+AC, CeramAlloy CP+AC, and DurAlloy

- Status Completed

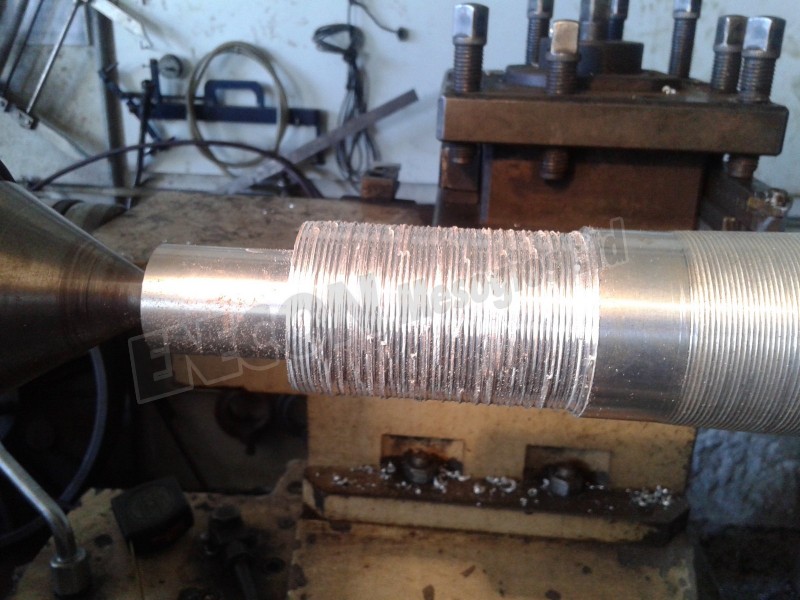

Two shafts (6m length, 14cm diameter) from mega-yachts suffered from corrosion. Following proper preparation, we managed to build & restore the shafts to their original shape/condition using ENECON DurAlloy of ENECON’s METALCLAD family of products . DurAlloy requires no heat, is machinable, trowelable, contains 100% solids, has unlimited shelf life (even when the packages are open), and is safe and simple to use. It may be difficult to accept but the repaired parts are even stronger than the original. The applications for the METALCLAD family are limitless (worn shafts, pumps, pipes (steam, heavy fuel, lub oil, MFO, seawater, etc.) condensers, cooler covers, cracked & holed casings, oversized bearing & bush housing, scored rams, sloppy keyways, stripped threads, warped, distorted or steam-cut flange faces, etc (sorry, not enough space).

METALCLAD DurAlloy is a two-component, 100% solids, multi-purpose polymer composite which can be easily machined on a lathe, drilled, tapped, filed, sanded and polished. For more information about METALCLAD DurAlloy please visit: METALCLAD DurAlloy

METALCLAD CeramAlloy CP+AC is a two component, 100% solids, polymer composite specifically formulated to provide effective repair and rebuilding characteristics on all types of fluid flow equipment. For more information about METALCLAD CeramAlloy CP+AC please visit: METALCLAD CeramAlloy CP+AC

METALCLAD CeramAlloy CL+AC is a 100% solids, two component, liquid polymer composite used for repairing, resurfacing and coating components to provide outstanding fluid flow erosion and corrosion resistance. For more information about METALCLAD CeramAlloy CL+AC please visit: METALCLAD CeramAlloy CL+AC