0280

- Industry Oil/Gas/Petrochemical

- Problem Chemical Attack and Corrosion / Erosion

- Country Cyprus

-

Project Goal

Protect from corrosion and damage

- Products Used CHEMCLAD SC

- Status Completed

A filter press is a tool used in separation processes, specifically to separate solids and liquids (e.g. from sludge). The process uses the principle of pressure drive, as provided by a slurry pump.

A plate and frame filter press is the most fundamental design and it consists of many plates and frames assembled alternately with the supports of a pair of rails.

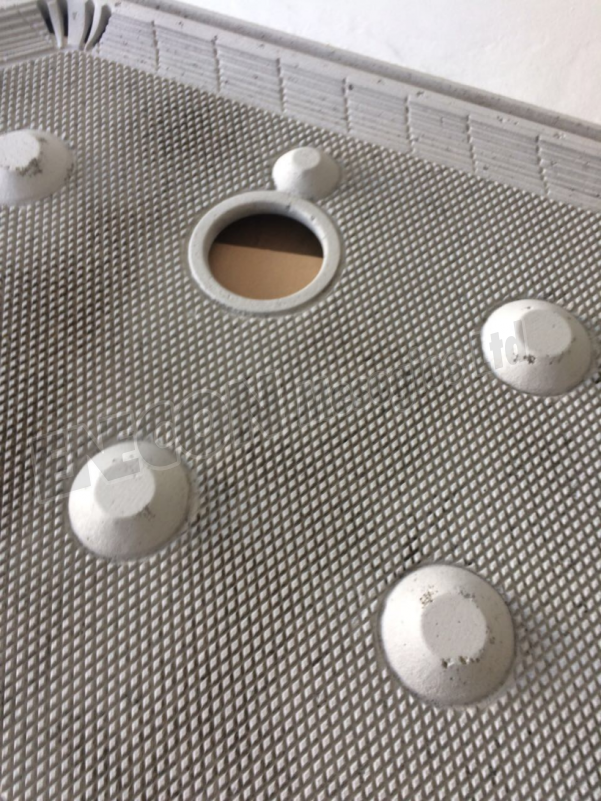

Filter plates are made from polymers or steel coated with polymer. They give good drainage surface for filter cloths. Plates generally last years unless they become cracked, broken or warped.

ENECON Mesogios was trusted two such plates in 2018 made out of steel that were suffering from extreme corrosion and damage. The client is a local company that collects and treats petroleum waste streams such as oily slops and sludge.

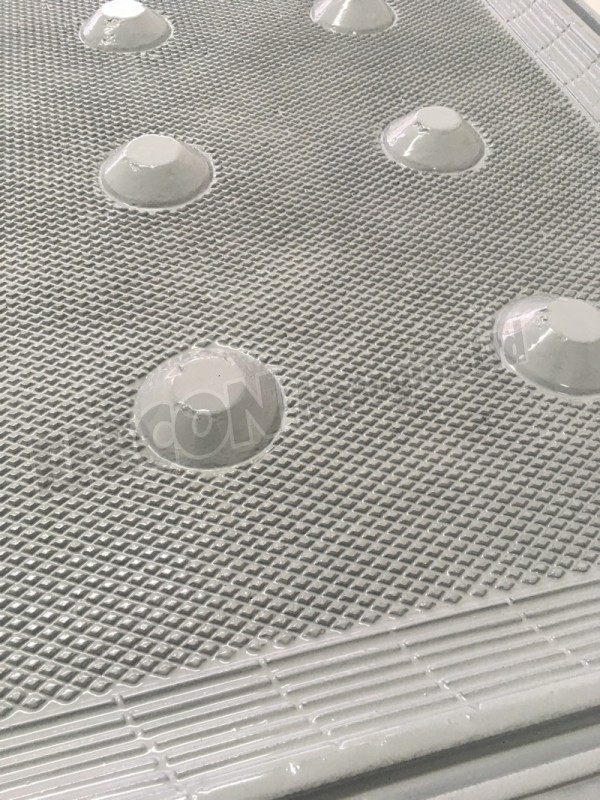

Client wanted these plates protected with a high performance coating in order to avoid constant replacements.

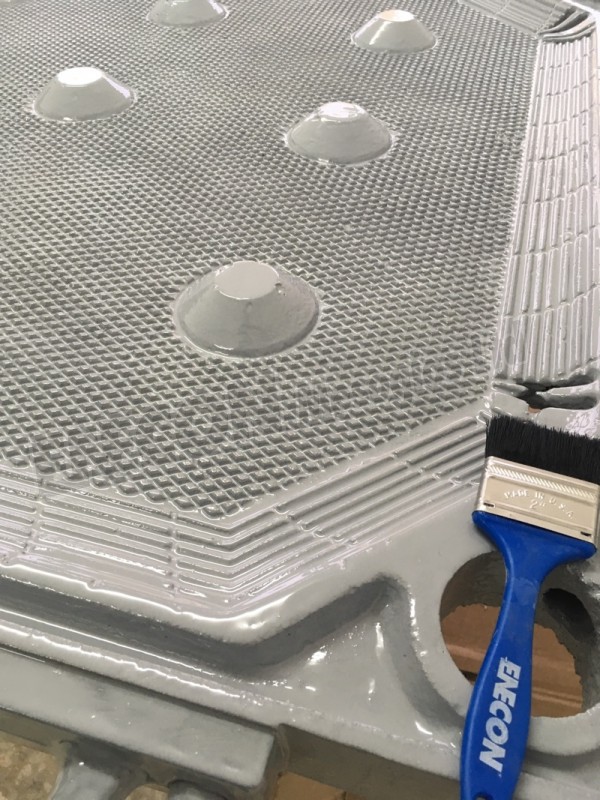

Our works included blasting to white metal finish and then we applied two coats of ENECON’s CHEMCLAD SC.