0143

- Industry General Industry

- Problem Safety Surfacing

- Country Croatia

-

Project Goal

Protection

- Products Used CeramAlloy CBX

- Status Completed

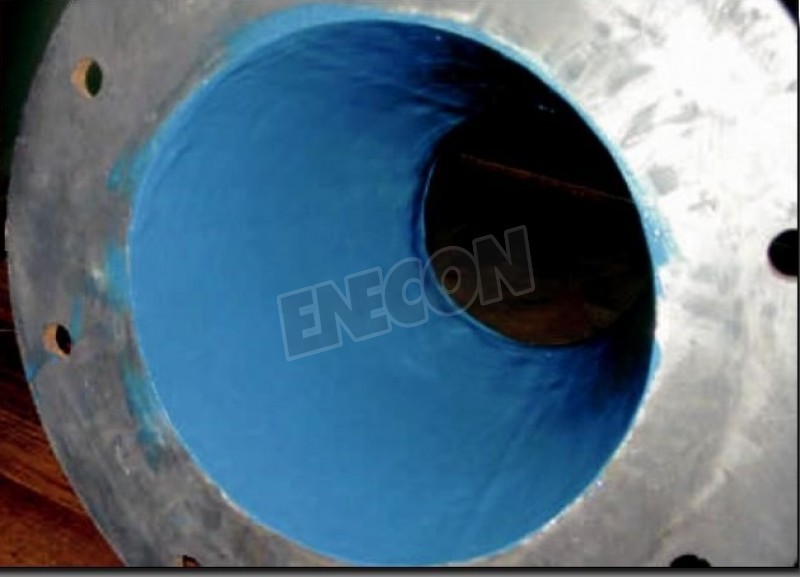

A local municipality on the Adriatic Sea in Croatia wanted to move a welding manufacturing plant from its seaside location to another site further inland. However, as part of this move, they were required to dispose of thousands of tons of slag which contained Silicon Manganese and Ferro Manganese, both of which have high re-sale values when separated. In order to do this effectively, these two metallic materials needed to be separated from the slag through cyclone separators – which typically must be repaired every month. The plant engineers wanted to see if they could find a more durable repair material so they conducted a side-by-side test utilizing a rubber liner for one CeramAlloy CBX Outperforms Rubber Liner & Hardface Welding cyclone, hardface welding on another and CeramAlloy CBX on a third cyclone. After three weeks the rubber liner and the hardfacing had both failed but the CBX was still providing excellent protection. The engineers selected our CBX as their standard repair material for this demanding application and immediately coated three additional spare cyclones.

METALCLAD CeramAlloy CBX is a three component, 100% solids, polymer composite specifically formulated to provide effective repair and rebuilding characteristics on all types of equipment subject to severe abrasion. For more information on METALCLAD CeramAlloy CBX please visit : METALCLAD CeramAlloy CBX