0306

- Industry Water/Waste water/Desalination

- Problem Heat Refractive Coatings and High Temperature

- Country United States

-

Project Goal

To reduce solar heat

- Products Used ENESEAL HR

- Status Completed

ENESEAL HR Receives International Acclaim. Independent Tests Confirm 28% Temperature Reduction on Metal Surfaces Exposed to Intense Solar Heat!

The internationally respected STANDARDS INSTITUTION OF ISRAEL, Industry Division, Hydraulics & Energy Laboratory, has completed a very thorough examination of our ENESEAL HR.

Obviously, minimizing heat load and saving energy are high on the list of priorities of companies in the Middle East. The intense desert sun can make metal and concrete structures unbearably hot. ENESEAL HR can help to reduce this solar heat load by as much as 28% according to the tests conducted by the Energy Laboratory.

These tests included sophisticated thermographic scans and photographs which clearly illustrate the incredible heat refractive properties of the ENESEAL HR coating system.

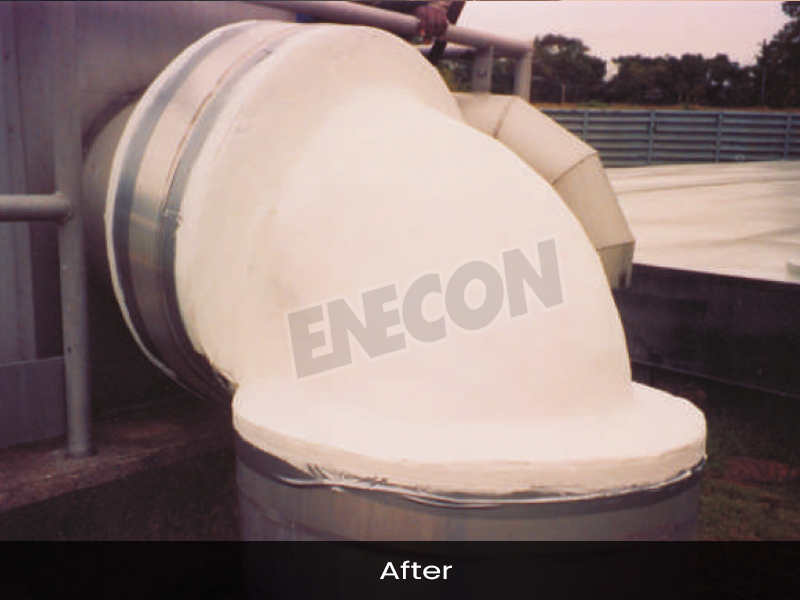

The Panama Canal Commission also conducted practical infield evaluations of our ENESEAL HR to determine its effectiveness in protecting pipe insulation in engine rooms from oil, water and steam impregnation. ENESEAL was found to be the best product and the most cost effective for these critical applications.

ENESEAL HR is truly in a class by itself when used as a heat refractive material as well as a protective system for all types of pipe and tank insulation.

The photos shown here (taken at a local Pennsylvania municipal water authority) illustrate just how simple and easy the ENESEAL HR system is to use. It can be applied by brush, roller or spray on virtually any type of surface…metal, concrete, asphalt/tar, slate, tile, wood, brick, glass, plastic, etc.

Clean-up is just as simple: soap and water is all that is needed.

Check out here other projects with this product, by ENECON.