0253

- Industry Oil/Gas/Petrochemical

- Problem Chemical Attack and Corrosion / Erosion

- Country Australia

-

Project Goal

To protect the 90 degree bend in the stack from the extremely corrosive environment

- Products Used CeramAlloy CL+AC

- Status Completed

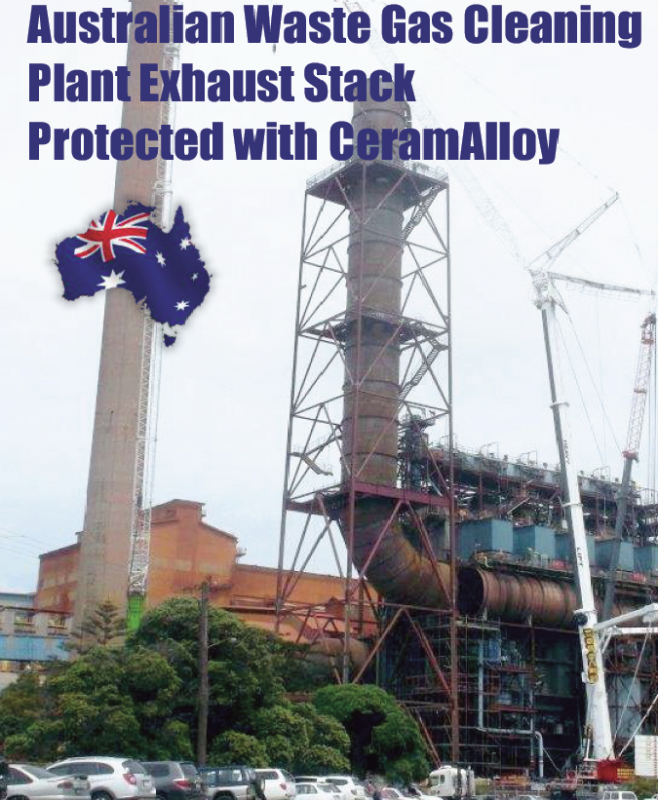

Waste gas from the steel making process is treated at this Australian waste gas cleaning plant. A new steel exhaust stack was being installed and the plant’s engineers wanted to protect the 90 degree bend in the stack (also known as the “lobster back”) from the extremely corrosive environment.

The 10 segments of the lobster back were grit blasted to a 75-100 micron (3-4 mil) profile. A mineral based blast media was first used to achieve the necessary level of cleanliness followed by an angular steel grit to achieve the necessary profile. This profile was extremely important to insure maximum adhesion as the temperature of this equipment operates up to 200° C (392° F) in this aggressive chemical environment.

Immediately after blasting, the first 2 layers of CeramAlloy CL+AC were spray applied using hopper guns. A third layer was then applied by roller and brush.

Overall, approximately 700 kg of CeramAlloy CL+AC were used and all 10 segments were completed on-time and on-budget.