0200

- Industry Water/Waste water/Desalination

- Problem Leak repairs

- Country United States

-

Project Goal

Stop Leakage

- Products Used CeramAlloy CL+AC, DurAlloy, and SpeedAlloy QS

- Status Completed

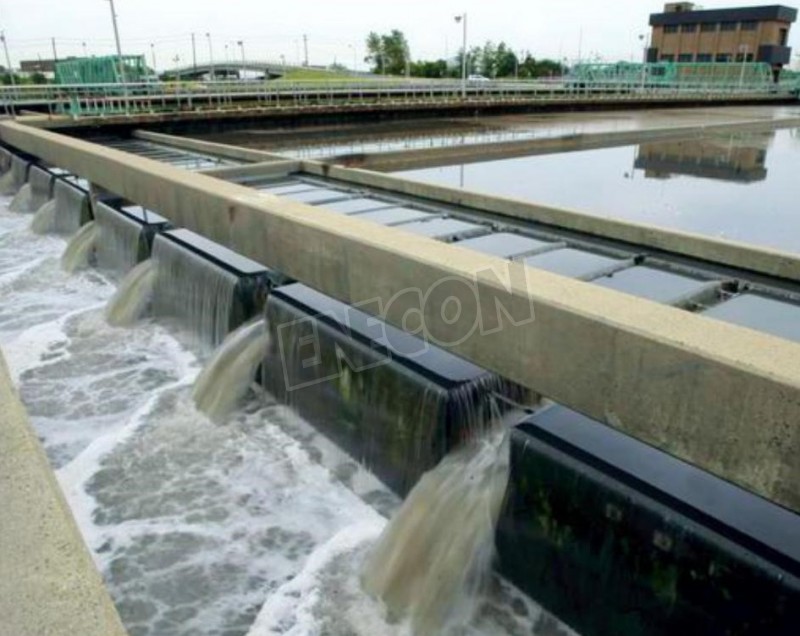

The coupling joints of these 48 inch diameter pipes were leaking. The pipes carry wastewater to clarifier tanks at the 5th largest wastewater treatment plant in the U.S. There are 12 of these pipes and they each have 3 couplings (36 total).

Numerous, unsuccessful, attempts to fix the leaks on these critical pipes had been made. Since the system could not be shut down to replace these couplings, the local ENECON Field Engineering Specialist was contacted to find a solution.

After a thorough examination, it was recommended that the couplings be grit blasted and SpeedAlloy QS be used to stop the active leaks. Once the leaks were stopped, CeramAlloy CL+AC (Gray) was used to wet out each side of the coupling and DurAlloy was applied to make any repairs.

A second coat of CeramAlloy CL+AC was applied to the entire coupling area, followed by a final top-coat of CeramAlloy CL+AC (Blue) to completely seal and encase the couplings.

The maintenance engineers were extremely pleased with the results and the ENECON Field Engineering Specialist is being given many other opportunities to provide solutions at this plant.